BLOG

Suspension Maintenance

Like any other component, suspensions wear out over time, especially because there is hardly any movement in the motorcycle; they are constantly at work. It doesn't matter whether these movements are short or prolonged, as they generally involve the displacement over the friction bushings and the transfer of oil from one chamber to another, resulting in the deterioration of all these components. And when these elements stop functioning correctly, it affects the malfunction of many others such as the frame, tires, and brakes.

Suspension maintenance is essential, more than we realize. Because when we think about suspension, in many cases, we only consider its setup or adaptation to our use. But beyond that, we have to think that with regular maintenance, we can extend its lifespan and preserve its dynamic qualities over time. In fact, the equation should almost be the other way around, and if someone asks about customization, the first thing to consider should be whether their suspensions are properly maintained. If they are well-maintained, setting them up comes next, not the other way around.

One of the most common mistakes is assessing the condition of our suspensions based on whether they are leaking oil or not, and obviously, this is a mistake. In reality, it's the mileage and hours of use that will indicate whether our suspensions are in perfect condition or in need of a check-up. Because an oil leak can occur at any time, not just due to a lack of maintenance.

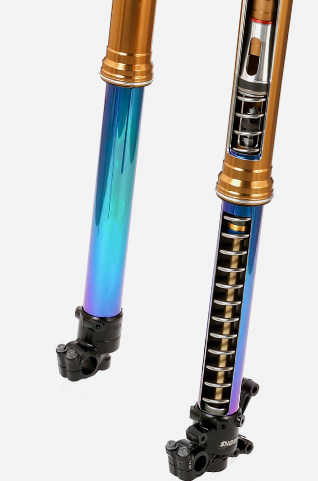

At this point in the post, we cannot overlook discussing the components that suffer the most in a suspension. There are four elements that deteriorate primarily. First, the seals, which are responsible for ensuring the system's tightness, preventing oil and air from escaping. Seals also protect the system from external agents such as water, mud, and more. Their exposure and soft material make them vulnerable.

The friction bushings are the second components and are responsible for facilitating the sliding of various suspension elements and preventing problems like stiffness or blockages that would prevent the suspension from ensuring the safe use of our motorcycle. Every time our vehicle is in motion, our suspensions move, generating friction on these bushings and the consequent wear and tear, resulting in increased tolerances between components and, in some cases, reducing sensitivity to movements.

The third component is the oil, whose main function is to create hydraulic resistance as it is forced through openings. This resistance or force is what ensures the controlled movements of our vehicle. Like the previously mentioned components, when there is minimal movement, the oil deteriorates. It heats up, and as we generate thermal work cycles, its components tend to separate, resulting in a loss of efficiency in its function.

And finally, the valves. One way to regulate the flow of oil from one chamber to another is by restricting passages with valves. These valves are part of a leaf spring system subjected to deformation based on the force exerted by the oil. The more we deform them, the more they wear out, leading to a decrease in performance.

So, you can imagine that it is crucial to keep all the elements of our motorcycle in perfect condition, and suspensions are one of them. Moreover, for a dirt bike used weekly, I recommend performing maintenance at least once midway through the season if it's new, and if it's used, do it once at the beginning and once at the midpoint.